Two kilometres as the crow flies from where I live is the Domaine du Grand Hazier, an estate comprising a main house, outbuildings, garden and orchard. It's also home to La Vanilleraie, a centre of vanilla production (more about that later). I first visited the estate about 15 years ago, and was glad of an opportunity to visit it again.

|

| looking down the majestic avenue of palm trees which leads up to the main house |

One of Réunion's one hundred first inhabitants, Jean Julien from Lyon, was granted the 600-hectare estate by the King of France in 1690. Over the years it changed owners several times until 1903 when Albert Chassagne acquired it, and the estate has belonged to the Chassagne family ever since, although it now only covers 100 hectares.

|

| the main house |

The current main house was built in the early 20th century, just before World War I, using the most modern techniques of the time, including a metal roof structure. It was the first house in Réunion to use this construction technique.

|

| metal roof structure of the main house |

|

| typical Creole cane chair on the varangue (verandah) |

The large one-storey house comprises a study, living room, six bedrooms, a kitchen/dining-room and bathroom, as well as 4 verandahs.

In the living room is a variation on the loveseat - a wide canapé for two fiancés who were not supposed to sit too closely to each other!

|

| fiancee loveseat, living room, Grand Hazier |

|

| kitchen/dining-room, main house, Grand Hazier |

Until fairly recently the house was inhabited by two elderly spinster aunts, the last remaining members of the family to live there. On our previous visit, I remember being told that their beds were made of camphor wood, which is supposedly anaphrodisiac(!).

|

| spinster aunts' bedroom |

The study holds originals and copies of correspondence both from previous owners and the Chassagne family.

In an age before photocopiers or computers, letter-writers could keep copies of their sent correspondence using a press like the one pictured below (for more details on how the presses worked see plates 1 to 6 here).

After visiting the house we moved into the kitchen garden, orchard and garden.

|

| Large staghorn fern |

|

| orange trumpet and cotton |

|

| cotton |

|

| jackfruit tree |

The estate is also surrounded by working sugar cane fields.

The estate's old stables (built in 1897) have been converted into La Vanilleraie, a vanilla production centre which can be visited by the public. Little vanilla is actually grown on the estate itself, most is grown elsewhere and sold to the Vanilleraie for processing.

After planting, the vanilla vine needs to be "curled": when it is too high it is folded down and fastened with string; when it is too low it is attached upwards. The lifespan of

a vanilla plant is about 20 years; it remains sterile during its first

four years, then it can produce up to 1 kg of green pods per year.

|

| "curled" vanilla vine |

The vanilla genus includes about one hundred species belonging to the orchid family. Only three species are grown for their aromatic properties. The most sought after, with the evocative name of vanilla fragrans (also known as vanilla planifolia), originates from Mexico.

|

| close up showing pods stamped with grower's ID |

In the wild

only one species of bee pollinates vanilla flowers, but this bee lives

in Mexico and nowhere else. So all vanilla flowers have to be

hand-pollinated - the method for doing this was discovered by a slave from Reunion, Edmond Albius, in 1841. In Reunion flowering takes place between September and December (so there were no flowers visible when we visited as it was July). An experienced worker can pollinate 1500-2000

flowers per morning.

|

| close-up of a new leaf |

Once it is pollinated the flower gives way to a green pod, which reaches its adult size after one month. Pod harvesting however takes place 8 months later (9 months after flower pollination), which is the time required for the pod to ripen. Pod ripening is marked by a change of colour from green to yellow. This is when the vanilla pods are harvested (between June and September), but after harvesting the yellow pods still need a year's work before they can be used.

|

| a basket of harvested pods before preparation starts |

The first step in pod preparation consists of hot water 'killing', also known as scalding. The 'killing' process stop the vegetative growth of the vanilla pods, and allows for controlled ripening. It consists of putting the pods in a basket and immersing them in water at 65°C (150°F) for three minutes.

|

| installation used for the hot water 'killing', also known as scalding, process |

Directly after removing the pods from the water they are put into wooden crates and wrapped in woollen blankets. The crates are then sealed tightly, the aim being to conserve the heat for as long as possible. The pods in the wooden crates should be left to "sweat" for at least twelve hours, after which they will have lost almost 20% of their weight through sweating, and will have become chocolate brown instead of yellow.

After twelve hours

in the wooden crates the chocolate brown pods need to be exposed to sunlight on

wooden racks for four to five hours a day for two weeks.

|

| racks of pods drying in the sun |

The racks need to be

set out every morning and brought in in the evening; if there is rain the racks

need to be taken in as the pods will become mouldy if they are in

contact with rain.

|

| racks of pods drying in the sun |

One hectare of vanilla may contain 2000 to 4000 vanilla plants, and 5 kgs of harvested yellow pods are needed to make 1 kg of dry pods.

|

| grower's ID visible on drying pod |

The next step consists of drying the pods in the shade, setting them out in the shade in a large room. After a month the pods are hand-sorted by a preparer who, according to the moisture content, decides whether the pod can proceed to the next step or if it should continue to dry in the shade. Each pod needs to be checked individually, as they do not all have the same moisture content. Sorting consists of rolling each pod between the fingers; if the pod rolls it needs to dry in the shade for a few more days, but if it sticks to the fingers it can proceed to the next preparation step. The dry pods (which stick to the fingers) are put into trunks for 8 to 9 months.

|

| pods drying in the shade |

After sorting by the preparer the pods are put into wooden crates, with parchment paper to avoid the pods touching the wood, to "macerate" for 9 months; during this period the distinctive vanilla aroma will develop.

Bourbon vanilla (or Bourbon-Madagascar vanilla), produced from Vanilla planifolia plants introduced from the Americas, is the term used for vanilla from the Indian Ocean islands of Reunion (formerly the Île Bourbon), Madagascar, and the Comoros. It is also used to describe the vanilla flavour derived from V. planifolia grown in tropical countries such as India.

During the first three months of fermentation the crates are checked for possible mouldy pods.

|

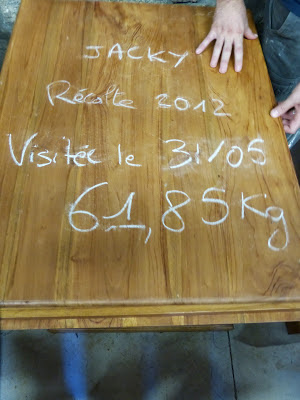

| this crate was checked for mouldy pods on May 31st |

Once the conditioning phase is over the pods are sorted into bundles according to size. Cracked pods are used for vanilla essence or powder.

|

| sorting and bundling the pods |

Once graded and bundled the vanilla is ready to be sold.

- Le Grand Hazier can be visited by appointment only (telephone 0262 52 32 81). Guided visits (€5/person) are in French.

- La Vanilleraie is open from Mondays to Saturdays: the shop is open from 9am-12pm and 2-5pm; guided visits (40 minutes; €5/adult, €3/child) are at 9am, 10am, 11am, 2pm, 3pm and 4pm. The website is in French only.

- For blog posts about visits to other historical estates on Reunion see Maison Rouge & the Indian Ocean Decorative Art Museum and Domaine de la Réserve & Ste Suzanne lighthouse.

- For a photo of a vanilla flower (growing in the wild) see Hiking in the Shadow of the Volcano.

No comments:

Post a Comment